Pedestrian Bridges, Road Bridges, Cycleway, Decks

Overview

Workflow

Modular Construction

Comparison against

other materialsAustralian Manufacturing

Installation Methodology

Standard Designs

Balustrade Options

Recycled Materials

Low Carbon Footprint

50 Year Warranty

Introduction

Welcome to the Future of Bridge Building

Until now, single element, lightweight large single span composite bridges have not been available to designers, architects, engineers and stakeholders in Australia & New Zealand.

Sustainable Infrastructure Systems (SIS) is proud to introduce Europe’s INFRACORE® Inside technology.

SIS is a unique organisation focused on manufacturing and distributing sustainable and recycled products and projects for diversified clients around the world.

From recycled plastic, recycled wood plastic composites (WPC), fiberglass reinforced polymers (FRP) and recycled rubber through to our CoreSpan® co-extruded multi-composites and aluminum WPC hybrid composite and OEM manufacturing, SIS are market leaders in delivering sustainable products to customers in many markets.

SIS specialise in delivering our product range to markets including Civil Infrastructure, Building & Construction, Oil & Gas, Mining, Aviation, Aquaculture, Marine & Ports, Transport & Logistics and Agriculture.

Products designed, manufactured and supplied by SIS embody state of the art technology and are engineered by our teams to deliver enhanced performance and sustainability effective operation for customers worldwide.

SIS has built a reputation based on excellent customer service, high quality manufacturing and on providing the right solution in sustainable product design and manufacturing.

Over

1,550 STRUCTURES

Delivered Worldwide

Continuous improvement of equipment design, materials and manufacturing technology ensures SIS maintains its capability of offering clients the latest and most commercially viable sustainable products and projects available.

SIS also works with clients to develop specific solutions to meet their unique needs through the application of research and development efforts in a partnering relationship.

Our Mission

SIS aims to set a responsible standard of sustainable product design and manufacture and project delivery for our diverse client base in both the short and the long term.

We all have a significant impact on the world around us and each of us should play a part in protecting future generations.

Designers, engineers and stake holders have a big responsibility to set standards of product and project design that benefits the environment and the people who live in it.

SIS’ aspiration is that ultimately, talking about sustainability will become superfluous, because it will be the expected.

We manufacture and supply

products from materials that include:

- Recycled Plastic

- Fiberglass Reinforced Polymers

- Recycled Wood Plastic Composite

- Recycled Rubber

- Co-Extruded Aluminium/

- Wood Plastic Composite

With a global network of manufacturing facilities, along with projects delivered in Africa, the Middle East, Asia, Australia and the Pacific Rim, combined with over 20 years of composite experience, SIS can be trusted to provide easy, efficient and seamless supply to almost any place on earth.

About Infracore®

In 1995, Jan Peeters developed Europe’s first publicly accessible composite bridge in Harlingen. His engineering firm Composieten Team worked together on the project with the Dutch Department of Waterways.

Although composite is in many respects superior to concrete, wood and steel, the application of this great material in heavily loaded constructions requires extra attention.

Jan Peeters resigned from the Plastic and Rubber Institute at TNO and focused all his attention on developing a revolutionary construction technology with composite.

Despite the long history of composites, these high-tech materials had not been paid much attention. It took almost 10 years before the inventions of Jan Peeters could be applied in infrastructure.

Together with Simon de Jong, Jan Peeters founded INFRACORE® Europe in 2008.

Workflow

By following this streamlined process, it is possible to have the INFRACORE bridge installed in less than 4 weeks, allowing for efficient and timely project completion.

01

01

Choose your standard INFRACORE bridge design:

Select the desired standard design for the bridge from the available options.

02

02

FRP Manufacturing (approx. 2 weeks*):

The manufacturing process begins, where the Fiber Reinforced Polymer (FRP) materials are used to construct the bridge components.This process typically takes around two weeks to complete.

02

03

Handrail Assembly (optional – approx. 1 week):

If a handrail is required for the bridge, it will be assembled during this stage. The handrail assembly typically takes around one week.

02

04

Packing and Delivery (1 week):

Select the desired standard design for the bridge from the available options.

02

05

Handrail Assembly (optional – approx. 1 week):

The bridge components are transported to the installation site, where the installation process takes place. A professional installation team can typically complete the installation within a day.

*subject to factory workload and raw materials availability

Modular Construction

The ability to construct elements off-site can dramatically improve how projects are delivered.

Ultimately, this method of construction provides significant benefits when it comes to maximising speed and safety and minimising disruption. The low weight of INFRACORE® elements and manufacturing off-site has some significant advantages;

- The disruption to surrounding road or rail infrastructure can be heavily reduced

- Safety risks for the construction of bridge elements are redirected towards the manufacturing plants – being controlled environments there is much less that can go wrong, when it comes to safety.

- Elements also benefit from being manufactured in a factory environment, avoiding the complications that can arise on a construction worksite.

- The construction speed will minimise building time and road closures. For construction work that is well prepared, a bridge with InfraCore® Inside can be installed within one hour.

- Production of bridge elements off-site means projects are more predictable when it comes to costs.

- Fewer labour elements necessary for constructing projects on site. This is a significant benefit when it comes to projects in congested or remote areas.

- Foundations required are approximately only one third of that required for concrete and steel constructions.

- As demand on scarce raw materials is reduced and emissions are very low, the technology is sustainable with regard to the environment.

100+ Year Design Life.

Virtually Maintenance Free

& Guaranteed For 25 Years

Structures with INFRACORE® Inside require no maintenance after installation. The materials used are not affected by moisture, rot, fungi, temperature, etc.

For this reason, INFRACORE® elements are covered by a 50-year guarantee. The outer surface of the bridges are finished in a high-quality gel coat or topcoat.

As this finish is based on the same polymer as the bridge, they form one consistent unit.

INFRACORE® is resistant to almost all forms of vandalism, such as graffiti and fire. Maintenance is limited to the cleaning and repair of the wearing surface. Repair will be required after the normal decrease of the roughness of the sacrificial layer.

Comparison against other materials

When comparing INFRACORE FRP bridges to traditional bridges made of steel, timber, or concrete decks, several factors come into play. Here is a comparison of some key aspects:

01

Weight

INFRACORE FRP bridges are significantly lighter than their traditional counterparts. FRP materials have high strength-to-weight ratios, allowing for the construction of lighter bridge structures. This advantage reduces transportation costs and simplifies installation, especially in remote or challenging locations.

02

Durability

FRP bridges offer excellent resistance to corrosion, making them highly durable even in harsh environments. Unlike steel bridges, FRP bridges do not rust, eliminating the need for frequent maintenance and repainting. Additionally, FRP materials are resistant to chemical corrosion, UV radiation, and extreme temperature variations, ensuring long-term durability.

03

Maintenance

Traditional bridges often require regular maintenance, such as painting, inspection for rust, and repairing deteriorated concrete or timber elements. In contrast, INFRACORE FRP bridges have low maintenance requirements. They do not corrode, rot, or decay, resulting in reduced maintenance costs over the bridge’s lifespan.

04

Design Flexibility

FRP bridges offer greater design flexibility compared to traditional materials. FRP composites can be molded into various shapes and sizes, allowing for customized designs that meet specific project requirements. This flexibility enables the creation of aesthetically pleasing bridges with unique architectural features.

05

Installation Speed:

INFRACORE FRP bridges can be installed relatively quickly. The lightweight nature of FRP components facilitates faster transportation, assembly, and installation processes. This advantage can lead to shorter project timelines and minimized disruption to traffic or the surrounding environment.

06

Sustainability:

FRP bridges have environmentally friendly characteristics. The manufacturing process of FRP composites consumes less energy compared to steel or concrete production. Additionally, the longevity and low maintenance requirements of FRP bridges contribute to reduced life-cycle environmental impacts.

07

Cost

While the upfront cost of FRP bridges may be higher than traditional bridges, they can provide cost savings over their lifetime. Factors such as reduced maintenance, lower transportation costs, and faster installation contribute to long-term cost-effectiveness.

It is important to note that the suitability of FRP bridges versus traditional bridges depends on specific project requirements, site conditions, and budget considerations. Consulting with engineering professionals and conducting a detailed feasibility study will help determine the most appropriate bridge solution for a given project.

Australian Manufacturing

SIS is a renowned certified manufacturer of INFRACORE® FRP bridges in Australia and New Zealand. We pride ourselves on utilizing the patented INFRACORE® Inside technology, ensuring the highest standards of quality and durability in our bridge constructions.

What sets us apart from our competitors is our dedication to local manufacturing. While many other companies rely on imported bridge products from overseas, we have our own state-of-the-art factory located in Wingfield (SA), where we produce FRP bridges right here in Australia. This localized production not only allows us to have better control over the manufacturing process but also ensures that our customers receive bridges that are specifically designed and constructed to meet the unique requirements of the Australian and New Zealand environments. With SIS, you can trust that our FRP bridges are built to last, providing safe and reliable solutions for various infrastructure projects.

With a global network of offices and manufacturing facilities, along with projects in Africa, the Middle East, Asia, Australia and the Pacific Rim, SIS can be trusted to provide easy, efficient and seamless supply to almost all places on earth.

Installation Methodology

Our INFRACORE FRP bridges offer a hassle-free and efficient installation methodology that sets us apart in the industry. Unlike traditional bridges with bolted connections, our bridges feature a drop-in installation system. This means that there are no complicated assembly processes or time-consuming bolted connections to deal with during installation. The entire process is streamlined and straightforward, saving you valuable time and resources on-site.

One of the key advantages of our INFRACORE FRP bridges is their exceptional longevity. With a 100-year design life and an impressive 50-year product warranty, our bridges are unmatched in Australia. This means that once installed, you can have complete peace of mind knowing that your bridge will stand strong and reliable for decades to come.

What sets our solution apart from others is not just its durability, but also its cost-effectiveness. Our INFRACORE FRP bridges are competitively priced, comparable to traditional FRP truss bridges with structural profiles or concrete/steel bridges. This means that you can enjoy the benefits of our innovative technology without breaking the bank.

When it comes to installation, our methodology is designed to be efficient and straightforward. First, the necessary civil works and preparation of the abutments are completed. Then, our INFRACORE FRP bridge is delivered to the site on a truck with a flatbed trailer, tailored to the size and width of the bridge. Using a truck crane, the lightweight bridge is easily lifted and dropped onto the prepared abutments. It’s a seamless process that eliminates unnecessary complications and ensures a smooth installation experience.

01

02

03

04

By choosing our INFRACORE FRP bridges, not only will you benefit from their exceptional quality and longevity, but you’ll also save valuable hours during the installation process.

This translates to higher profits for the main contractor in charge of the installation, making it a no-brainer choice for infrastructure projects.

With our INFRACORE FRP bridges, installation is efficient, reliable, and hassle-free, allowing you to focus on delivering successful projects with confidence.

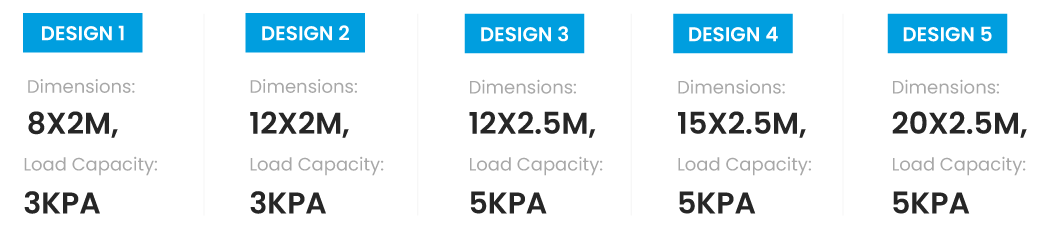

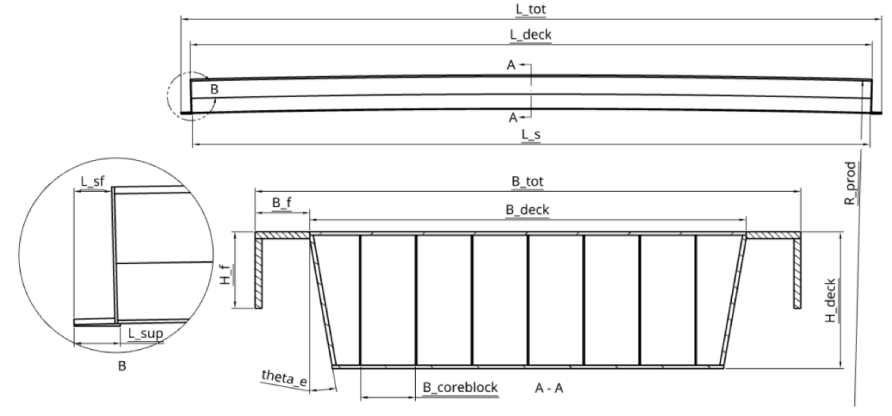

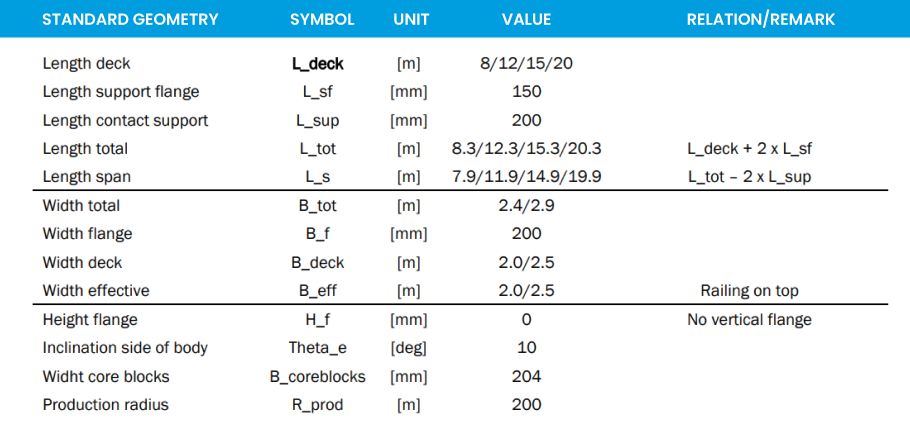

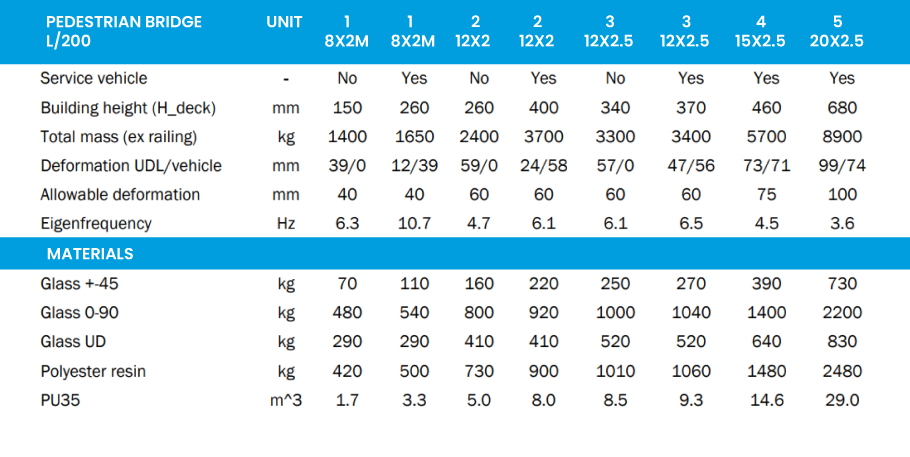

Standard Designs

INFRACORE products are dedicated to providing comprehensive and innovative solutions for your infrastructure needs. Our pre-designed options offer a range of sizes and load capacities to accommodate various project requirements. With a focus on structural integrity and performance, our designs are engineered to meet stringent industry standards

Design Options:

It is important to note that the length provided (8m, 12m, 15m, 20m) represents the deck length, while the width (2m, 2.5m) represents the effective width, which refers to the space between the railings.

Our designs are carefully crafted to cater to various project requirements, with options available for both the presence and absence of a 12-ton service vehicle. This flexibility ensures that our solutions can be seamlessly integrated into different applications, including but not limited to transportation infrastructure, industrial facilities, and public spaces.

Design Requirements

To ensure optimal performance and longevity, our designs meet specific requirements, including:

1. Allowable Deformation: The decks are designed to withstand live traffic loads with minimal deformation. We adhere to industry standards, maintaining allowable deformation ratios of L/300 or L/200, where L represents the span length.

2. Minimum Unloaded Eigenfrequency: We prioritize the safety and comfort of users. Our designs are engineered to achieve a minimum unloaded eigenfrequency of 3.0Hz, ensuring stability and reducing vibrations.

Here is an overview of the pre-designs, categorized into two tables based on their deformation requirements. The first table includes designs that meet the stringent L/300 deformation requirement, while the second table consists of designs that meet the less stringent L/200 deformation requirement, which is normally employed for FRP bridges.

For Design 4 and Design 5, the deformation caused by the uniform distributed load is a driving factor in the design. As a result, there is no distinction in the design specifications between the configurations with and without a service vehicle.

Standard Design 3

Dimensions: 15×2.5m, Load Capacity: v5kpa (CASE STUDY: Nalang Creek Pedestrian Bridge)

The Nalang Creek Pedestrian Bridge project presented a unique set of design challenges due to the location’s sensitive environment and the presence of a majestic 100-year-old tree. Our team was tasked with ensuring that the bridge seamlessly coexisted with the natural surroundings while preserving the tree’s historical significance. This required meticulous planning and innovative engineering techniques to minimize environmental impact.

One of the critical challenges was the careful lifting and positioning of the bridge near the ancient tree. The engineering team had to take extra precautions to ensure the tree’s health and stability were not compromised during the construction process. Rigorous studies were conducted to determine the optimal location for the bridge’s foundations, with a delicate balance struck between maintaining a safe distance from the tree and accommodating the structural requirements of the bridge.

Moreover, the project team had to address sustainability concerns, keeping in mind the local ecosystem and environmental impact. Considerations were made to minimize the project’s carbon footprint, such as utilizing sustainable materials, implementing eco-friendly construction practices, and incorporating energy-efficient lighting solutions for the bridge.

Another significant challenge was the presence of power lines near the construction site, requiring careful planning to ensure the safe lifting and cranage operation of the bridge. Collaborating closely with utility companies and expert technicians, our team devised innovative solutions to reroute and temporarily disable power lines during the critical lifting phase. This meticulous approach mitigated any potential hazards, ensuring the safety of the construction crew and minimizing disruption to the local power supply.

Successful Outcome and Inauguration: Despite the numerous challenges, the Nalang Creek Pedestrian Bridge project was completed with resounding success. The council, impressed by the design and execution, recognized the bridge as a marvel of engineering, seamlessly blending with the natural environment. To celebrate this achievement, the council organized a grand inauguration ceremony, inviting numerous community members to participate in the ribbon-cutting event. inviting numerous community members to participate in the ribbon-cutting event.

The bridge has not only enhanced the connectivity between the communities on either side of the creek but has also become a symbol of sustainable infrastructure development. Its seamless integration with the surroundings, combined with the careful preservation of the ancient tree, has garnered admiration from both locals and visitors alike. The council’s decision to showcase the bridge through the inauguration event reflects their pride and recognition of its positive impact on the community.

Standard Design 5

Dimensions: 20×2.5m, Load Capacity: 5kpa (CASE STUDY: Thompson Drain Pedestrian Bridge)

The Thompson Drain Pedestrian Bridge project was commissioned by Melbourne Water and involved the construction of a 20m pedestrian bridge over the Thompson Drain waterway in Melbourne, Australia. The bridge was designed to provide a safe and accessible crossing for pedestrians and cyclists, connecting the local community to nearby amenities.

The project team faced several challenges during the implementation of the Thompson Drain Pedestrian Bridge. Firstly, the project site was located near a busy road, which meant that safety was a top priority during construction. Secondly, the bridge had to be constructed over the Thompson Drain, which required careful planning and coordination with Melbourne Water to ensure compliance with environmental regulations.

To overcome these challenges, the project team developed a comprehensive safety plan that included the deployment of safety barriers and signage to protect workers and road users. The team also worked closely with Melbourne Water to obtain the necessary permits and approvals for the project.

In terms of construction, the bridge was designed to be lightweight and easy to install. The Infracore bridge was chosen for its ease of assembly and light weight and was transported to the site in pre-assembled sections. Using a crane, the bridge sections were lifted onto the abutments and secured in place, with finishing touches added to ensure a safe and accessible crossing for pedestrians and cyclists.

The successful completion of the Thompson Drain Pedestrian Bridge project resulted in a safe and accessible crossing for pedestrians and cyclists over the waterway. The Infracore bridge provided a costeffective and efficient solution for the project, as its lightweight design reduced installation time and costs. The project also demonstrated the importance of effective planning and coordination with Melbourne Water and other stakeholders to ensure compliance with regulations and safety standards

Balustrade Options

01

FRP POST WITH ALUMINUM INFILLS:

- This option combines FRP (Fiber Reinforced Polymer) posts with aluminum infills for the balustrade.

- FRP posts offer excellent corrosion resistance, durability, and low maintenance requirements.

- Aluminum infills provide structural strength and can be designed in various patterns and styles.

- The combination of FRP and aluminum creates a visually appealing and robust balustrade system

Options 1

When selecting a balustrade option for an INFRACORE bridge, factors to consider include design preferences, structural requirements, durability, maintenance needs, and compliance with safety regulations. Consulting with a professional engineer or bridge designer will help determine the most suitable balustrade option based on the specific project requirements.

02

STEEL MONORAILS:

- This option involves using steel monorails as the primary structure for the balustrade.

- Steel monorails provide high strength and stability for the balustrade, ensuring safety and security.

- The steel monorails can be designed with various shapes and profiles, allowing for customization.

- This option is suitable for projects that require a more traditional or industrial aesthetic.

Options 2

When selecting a balustrade option for an INFRACORE bridge, factors to consider include design preferences, structural requirements, durability, maintenance needs, and compliance with safety regulations. Consulting with a professional engineer or bridge designer will help determine the most suitable balustrade option based on the specific project requirements.

03

FRP POST WITH FRP INFILLS:

- This option utilizes FRP posts along with FRP infills for the balustrade system.

- FRP posts offer corrosion resistance, durability, and low maintenance, similar to the FRP post with aluminum infills option.

- FRP infills are made from composite materials and can be designed in different patterns and styles.

- Using FRP for both the posts and infills provides a cohesive and visually consistent balustrade solution.

Options 3

When selecting a balustrade option for an INFRACORE bridge, factors to consider include design preferences, structural requirements, durability, maintenance needs, and compliance with safety regulations. Consulting with a professional engineer or bridge designer will help determine the most suitable balustrade option based on the specific project requirements.

Balustrade Options

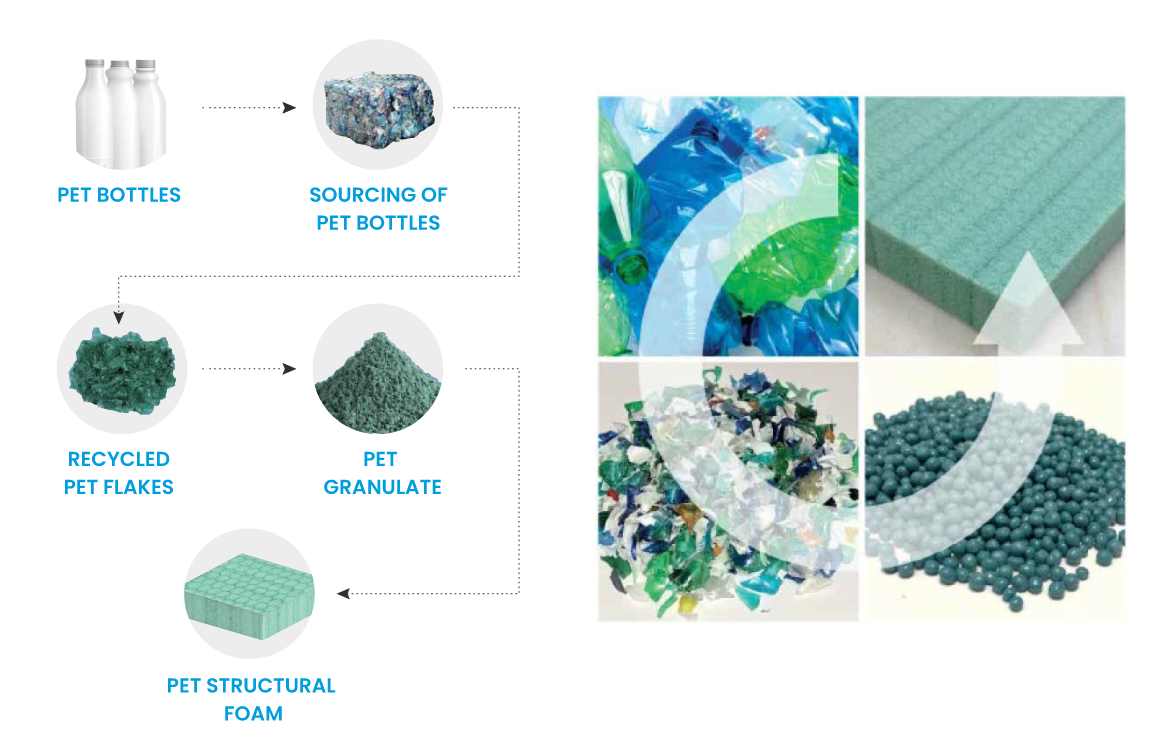

Infracore Structural Core Recycled Materials:

High quality composite core material made form end-grain balsa with exceptional shear and compressive strength

A structural foam core using a SAN polymer base featuring high toughness and impact resistance characteristics

A recycled PET foam suitable for sandwhich core applications with an excellent strength to stiffness ratio

Closed cell, cross-linked PVC foam, provides superior strength to weight ratio

Balustrade Options

Since 2010, the use of Fibre Reinforced Polymer (FRP) composites in civil engineering and pedestrian infrastructure construction has significantly increased. In North America and Europe, over 2800 FRP bridges and boardwalks have been built, providing maintenance-free infrastructure assets that can last for over 100 years.

In Australia, FRP is becoming the preferred material for lightweight civil engineering structures, with government entities embracing its benefits.

FRP offers peace of mind to infrastructure managers, eliminating the stress of maintenance budgets, while designers can break free from conventional structural shapes and create designs that align with the urban context.

Installing contractors appreciate the speed of construction, reduced on-site times, and cost reductions, giving them a competitive edge in tender applications and allowing them to focus on groundworks. The adoption of FRP technology contributes to a low-carbon footprint and sustainable infrastructure development.

InfraCore FRP structures can reduce project carbon significantly CSIS

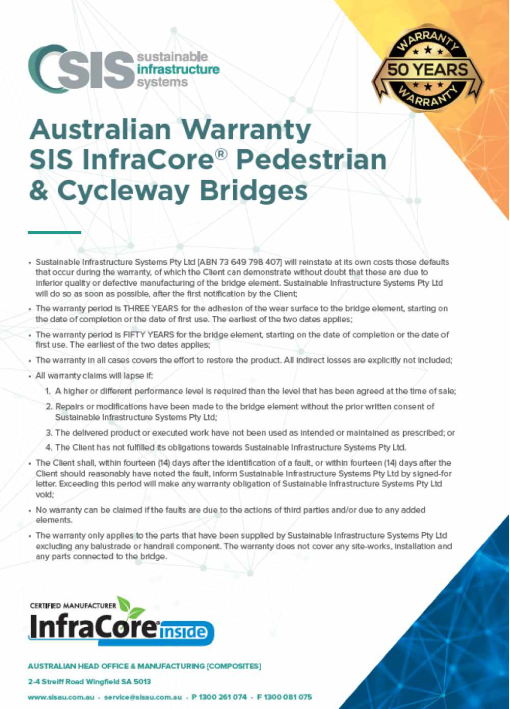

50 Year Warranty

Our INFRACORE FRP technology is backed by an impressive 50-year product warranty and designed to last for a remarkable 100 years. This exceptional warranty and design life highlight the unparalleled durability and longevity of our FRP solutions. We take pride in delivering products that not only meet the highest quality standards but also provide long-term reliability and peace of mind to our clients.

With a 50-year product warranty, we stand behind the performance and structural integrity of our INFRACORE FRP technology. This warranty ensures that our products are free from defects and will maintain their strength and functionality for five decades. It reflects our commitment to producing high-quality FRP solutions that can withstand the test of time and deliver consistent performance throughout their lifespan.

Moreover, the 100-year design life of our INFRACORE FRP technology demonstrates our dedication to engineering solutions that are built to last. We meticulously design our FRP products with longevity in mind, considering factors such as environmental conditions, load capacities, and material properties. This ensures that our bridges and structures can withstand the rigors of various applications and provide reliable service for a century.

By choosing our INFRACORE FRP technology, clients can have full confidence in the longevity and performance of their infrastructure investments. Whether it’s a bridge, deck, or other FRP structure, our products are designed to endure and maintain their structural integrity over time. This longevity not only reduces maintenance and replacement costs but also contributes to the sustainability of projects, promoting a more sustainable and resilient built environment.

With the combination of a 50-year product warranty and a 100-year design life, our INFRACORE FRP technology sets the standard for long-lasting, reliable, and cost-effective infrastructure solutions. We are proud to offer a level of quality and assurance that exceeds industry norms, providing our clients with the peace of mind and confidence they need for their projects’ success.